Product Introduction:With the continuous expansion of the use of plastic molding products, from the

Email: info@standard-groups.com

Product Introduction:

With the continuous expansion of the use of plastic molding products, from the point of view of the surface appearance of molded products (creativity), improving scratch resistance (scratch characteristics) has become an important topic. And scratch resistance is also very important from the point of view that scars formed on the surface of the molded product may reduce the strength of the product. Scratch testing is performed by horizontal movement of the scratch needle against the pattern. Scratch characteristics were previously evaluated by a "constant vertical load test", but the American Society for Materials and Testing (ASTM) and the International Organization for Standardization (ISO) standardized the "vertical load test" (ASTM D7027-05/S019252)。

Scope of application:

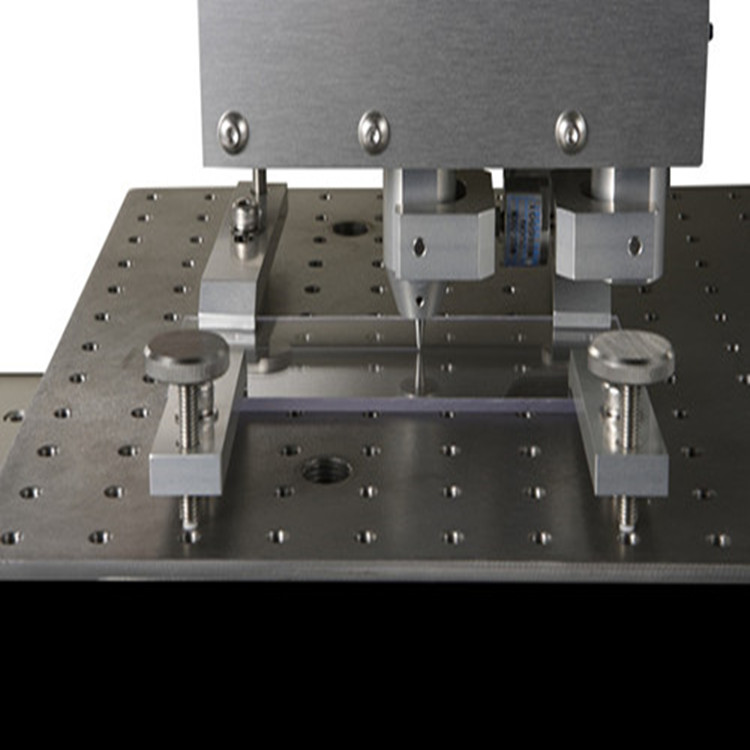

The tester uses a steel needle to scratch films, plastics, automotive interior and exterior decorative materials, coating materials, etc., to evaluate the material's "scratch resistance" (scratch characteristics)。

Features of scratch tester:

1. Teaching function

Use this function to set the load zone with high precision before sampling.

2. Easy to operate with touch screen

All functions can be used and configured through the touch screen installed in front of the Settings.

3, the surface has a bump can also test scratches

The Yaru drive for vertical loads uses a county frame mechanism, so that even the surface with a concave and convex pattern can be tested without affecting the linear increase in load characteristics.

4. Memorizable test conditions

Technical parameters:

Storage capacity up to 20, capable of memorizing test conditions.

The KK-01 is fully compliant with I50 and ASTM International standards

Size/weight (rough value):W965xD530xH690(mm)/150kg

Power supply :AC100V, maximum power consumption 60W

Measure ambient temperature and humidity :10 to 40 ° C ° C /30 to 70%RH Non-condensing.

※ Install in places less affected by wind or vibration

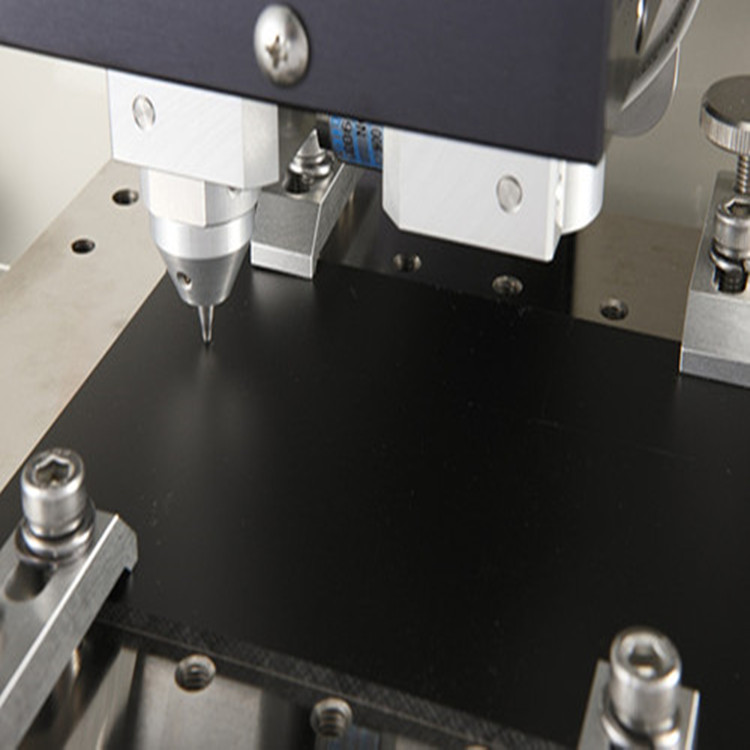

Measurement method: increased load method

Scratch direction: from left to right

Detector: Force sensor

Vertical load :1——200N

Horizontal load (Max.):200N

Accuracy (full scale):±0.5% or less

Detector: linear encoder

Distance (Max.):400mm

Scratch speed :1mm/sec——400mm/sec

Detection depth: Detector: Laser displacement meter

Data communication: Data transfer :USB

Number of measurement results: about 1000

Sample size: Size :200mmx420mm Degree :5mm(Max)

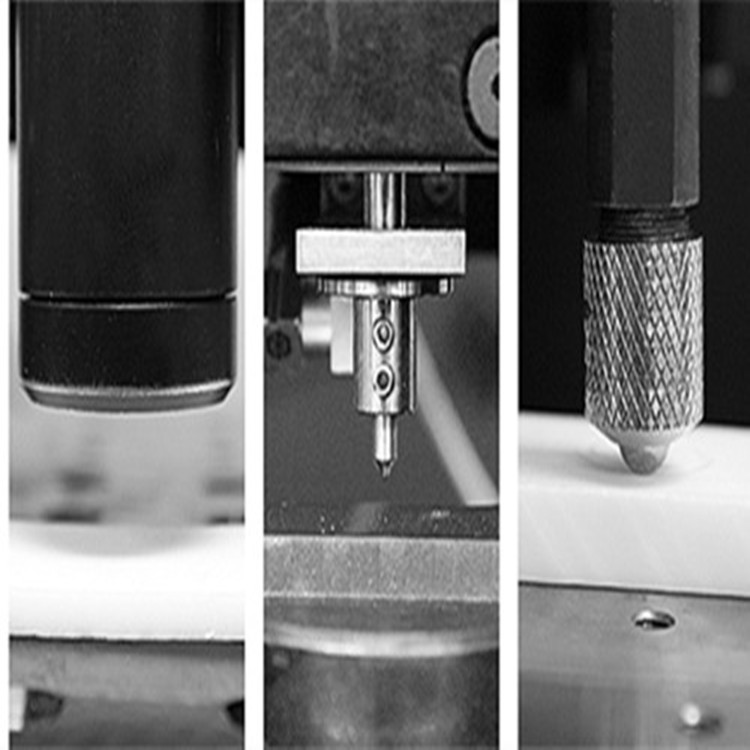

Chip type:

In addition to the standard φ1mm chip, a variety of chips are available to facilitate evaluation of a wide range of scratch damage (gloss scratch, scale scratch, cut scratch, etc.)。 Custom testing of chips to meet customer needs is also accepted.

※ Except φ1mm chip, does not meet ASTM, ISO standards

Disclaimer: The above content is for reference and communication only among industry insiders, and does not guarantee its accuracy or completeness. According to relevant laws and regulations and the regulations of this website, units or individuals who purchase related items should obtain valid qualifications and qualification conditions.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com