Performance Parameter◆ Sample Pretreatment and Analysis Stations: 2 sample pretreatment degassi

WhatsApp: +86 13816217984

Email: info@qinsun-lab.com

◆ Sample Pretreatment and Analysis Stations: 2 sample pretreatment degassing stations, 1-2 sample analysis stations, with the degassing system and analysis system operating completely independently without interference;

◆ Fully Constant Temperature Analysis of Vapor Adsorption: Capable of performing fully constant temperature analysis of vapor adsorption, with a maximum constant temperature of up to 105℃;

◆ Closed Constant Temperature System: Closed constant temperature control for the entire gas path, including sample tubes in the adsorption chamber, manifold modules, valve blocks, etc., at the test position, ensuring no cold spots in the entire adsorption system;

◆ Vapor Generation System: The instrument is equipped with a fully constant temperature vapor generation system to ensure accurate quantification of vapor;

◆ Oil-resistant and Corrosion-resistant Design: All pipelines and valve seals adopt oil-resistant and corrosion-resistant designs, with priority given to VCR hard connections; for some rubber ring seals, oil-resistant and corrosion-resistant perfluoroelastomer is used;

◆ Specialized Valves Resistant to Oil and Organic Vapor Corrosion: All valves are specialized valves resistant to oil and organic vapor corrosion, suitable for adsorption and desorption analysis of organic vapors and petroleum products;

◆ Fully Automated and Intelligent Operation: Fully automated and intelligent operation without the need for manual supervision, with user-friendly voice operation prompts;

◆ Independent High-precision Saturated Vapor Pressure (P0) Real-time Testing Station;

◆ Dual Cold Trap Protection for Vacuum System and Molecular Pump: Cold traps effectively capture high-boiling adsorbates, which is an essential device for vapor adsorption analysis;

◆ Non-blocking Anti-contamination Device: Completely resolves the issue of sample contamination of the system, affecting instrument stability;

◆ Intelligent Self-inspection Process: Intelligently judges whether sample tubes are installed, whether the tube jackets are tightened, and whether there is air leakage;

◆ Detailed Instrument Operation Log Display and Recording: Can be accurate to the second, with full experimental records traceable;

◆ Superior Stability: Even in the event of accidental power outages or disconnections, current data will not be lost, and the experiment can be resumed and continued;

◆ Intelligent Dual-mode Gas Injection Control: Improves experimental efficiency while ensuring experimental accuracy;

◆ Multi-channel Independent Gas Inlet: Supports more than 4 independent gas inlets, allowing for vapor adsorption of special gases such as ammonia (optional), benzene, toluene, ethanol, formaldehyde, water vapor, etc., and testing of non-corrosive gases such as nitrogen, oxygen, hydrogen, argon, krypton, carbon dioxide, methane, etc.

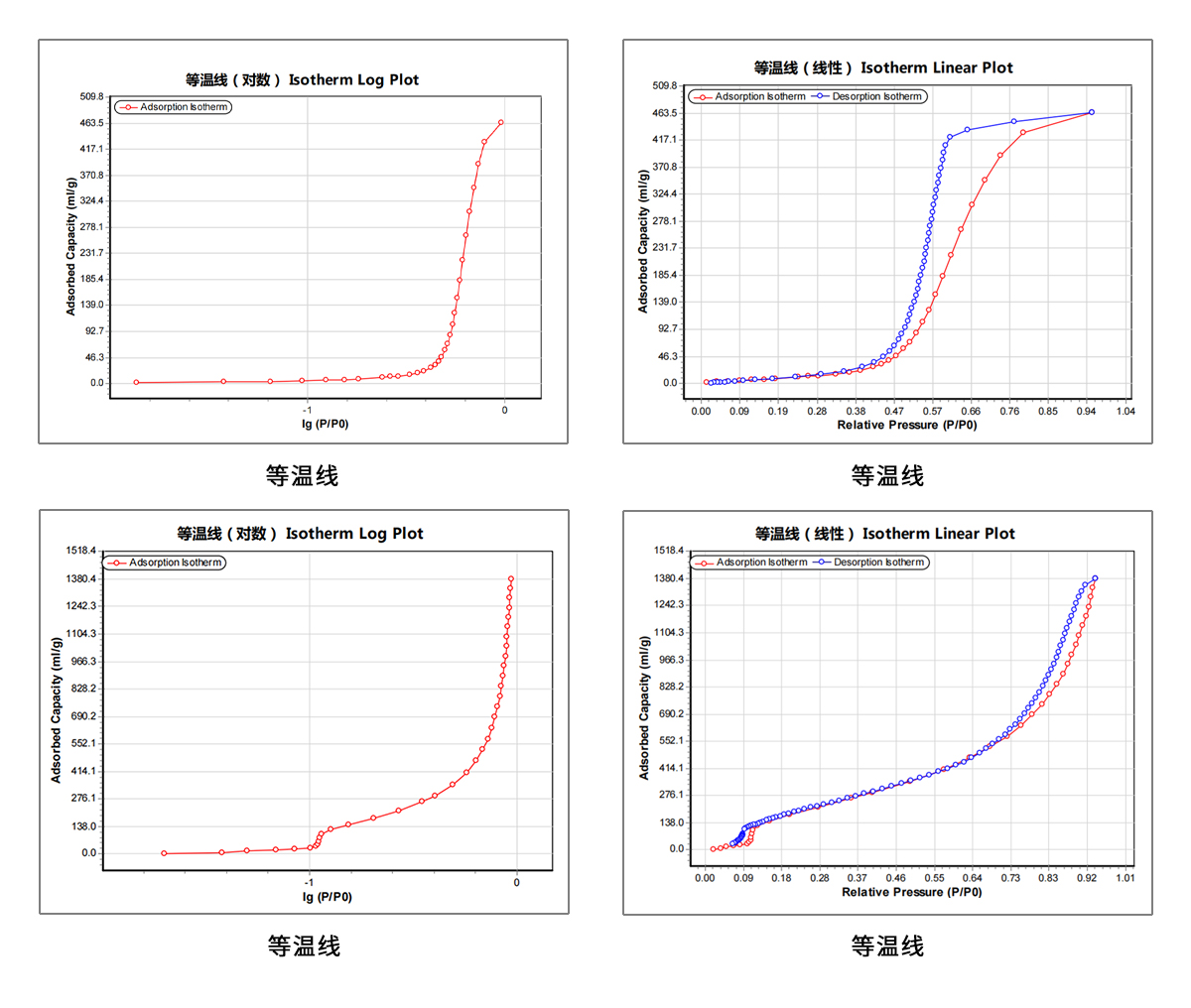

◆ Fully Constant Temperature Vapor Adsorption/Desorption Isotherms

◆ Low-temperature Nitrogen Adsorption/Desorption Isotherms

◆ BET Specific Surface Area

◆ BJH Method for Pore Volume and Pore Size Distribution

◆ MK-plate Method (Parallel Plate Model) for Pore Volume and Pore Size Distribution

◆ t-plot Method for Micropore Analysis

◆ MP Method (Brunauer) for Micropore Analysis

◆ D-R Method for Micropore Analysis

◆ HK Method for Micropore Analysis

◆ DFT Method for Pore Size Analysis of Micropore Distribution

◆ Total Pore Volume Measurement

◆ Average Pore Size Test

◆ Testing Capabilities for Corrosive and Non-corrosive Gases, Organic Solvents, Water, etc.

◆ IAST Model for Mixed Gas Adsorption

Disclaimer: The above content is for reference and communication only among industry insiders, and does not guarantee its accuracy or completeness. According to relevant laws and regulations and the regulations of this website, units or individuals who purchase related items should obtain valid qualifications and qualification conditions.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com